參考價格

面議型號

500-5000升品牌

力加力產地

武漢市樣本

暫無產量:

10噸裝機功率(kw):

350成品細度:

1um入料粒度(mm):

5工作原理:

介質研磨粉碎程度:

超細粉碎看了不銹合金鋼超耐磨研磨桶的用戶又看了

留言詢價

留言詢價 電話詢價

電話詢價

虛擬號將在 180 秒后失效

使用微信掃碼撥號

本圖使用氧化鋯0.6mm研磨珠,每秒11米速度,連續運行8500小時打開機器情況,無磨損、無銹蝕、無變形,產品質量符合指標要求。

本公司生產的超耐磨不銹合金鋼研磨內筒:采用優質不銹合金鋼,經先進工藝精制而成,適用于金屬、非金屬礦、高溫重油及化工鈦白粉等物料的研磨作業。產品具備使用壽命長、超強耐磨、耐腐蝕性佳等特點,且不會對物料造成污染,使用成本優勢顯著。

可生產及更換500升、1000升至5000升容積的國內外砂磨機研磨內筒,支持內外研磨筒整體交付,也可單獨更換研磨內筒(單獨更換需在供方生產場地進行)。

目前,我公司的不銹合金鋼超耐磨研磨內筒已成功應用于鈦白粉(Tio?)研磨場景,搭配0.6-0.8mm氧化鋯95研磨介質,在11m/s線速度下運行,設計使用壽命可達10年以上。現有案例中,同款產品經5年實際生產運行后無明顯磨損,廣受用戶認可,歡迎預約前往用戶使用現場實地考察。

The super wear-resistant stainless alloy steel grinding inner cylinder produced by our company: It is made of high-quality stainless alloy steel through advanced craftsmanship, and is suitable for grinding operations of materials such as metals, non-metallic minerals, high-temperature heavy oil, and chemical titanium dioxide. The product features long service life, super wear resistance, and excellent corrosion resistance. It will not pollute materials and has significant advantages in terms of usage cost.

We can produce and replace grinding inner cylinders of sand mills at home and abroad with volumes ranging from 500 liters, 1000 liters to 5000 liters. We support the overall delivery of inner and outer grinding cylinders, and can also replace the grinding inner cylinder separately (separate replacement needs to be carried out at the supplier's production site).

At present, our company's super wear-resistant stainless alloy steel grinding inner cylinder has been successfully applied in titanium dioxide (TiO?) grinding scenarios. Equipped with 0.6-0.8mm zirconia 95 grinding media and operating at a linear speed of 11m/s, its designed service life can reach more than 10 years. In existing cases, the same product shows no obvious wear after 5 years of actual production operation, which is widely recognized by users. You are welcome to make an appointment to visit the user's application site for on-site inspection.

使用氧化鋯0.6mm研磨珠,每秒11米速度,連續運行2500小時打開機器情況,無磨損、無銹蝕、無變形,產品質量符合指標要求。

可以生產和更換500升1 000升-5 000升容積國內外砂磨機研磨內筒。可以內外研磨筒整體交貨或單獨更換研磨內筒也行(單獨更換內筒須在供方生產場地進行)。我公司不銹合金鋼研磨內桶已經成功應用Tio2

2022-03-26

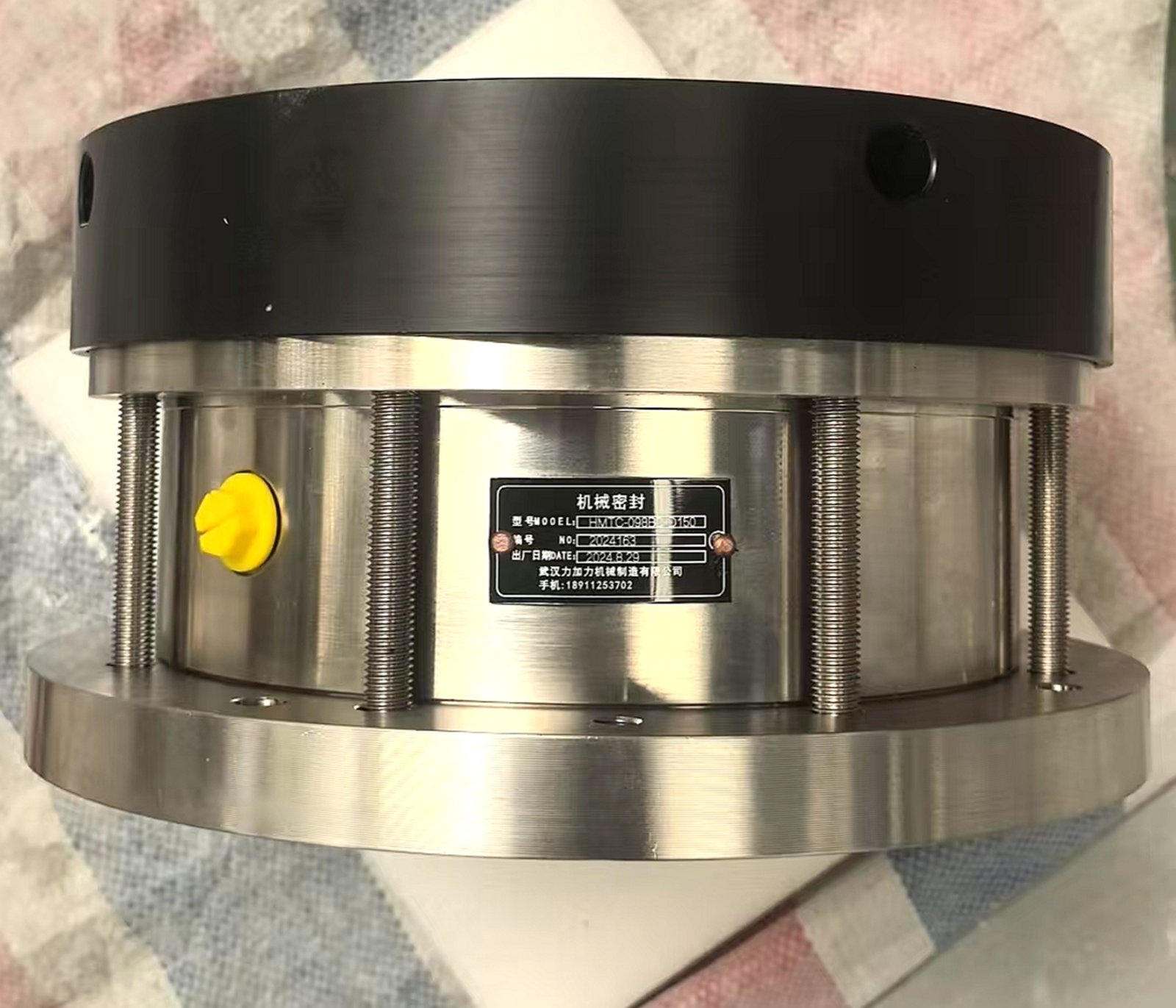

在炎炎夏日的高溫環境下,為江西用戶的砂磨機更換軸承和機械密封時,需特別注意高溫作業安全和設備維護的精準性。以下是關鍵步驟和注意事項: 一、前期準備1. 防暑降溫措施 - 選擇早晚溫度較低時段作業,

2025-07-25

納米砂磨機在芯片光刻

砂磨機作為一種高效超細研磨設備,在鈾礦開采及核能發電產業鏈中發揮著不可替代的作用,其應用貫穿鈾礦提取、反應堆材料制備、燃料加工及核廢料處理等關鍵環節,推動著核能產業向高效、安全、環保方向發展。一、鈾礦

在全球能源轉型與礦產資源開發的雙重浪潮中,砂磨機作為關鍵研磨裝備正加速向大型化邁進。這一趨勢不僅是工業技術迭代的必然結果,更是能源與礦業領域降本

不銹合金鋼超耐磨研磨桶的工作原理介紹?

不銹合金鋼超耐磨研磨桶的工作原理介紹? 不銹合金鋼超耐磨研磨桶的使用方法?

不銹合金鋼超耐磨研磨桶的使用方法? 不銹合金鋼超耐磨研磨桶多少錢一臺?

不銹合金鋼超耐磨研磨桶多少錢一臺? 不銹合金鋼超耐磨研磨桶使用的注意事項

不銹合金鋼超耐磨研磨桶使用的注意事項 不銹合金鋼超耐磨研磨桶的說明書有嗎?

不銹合金鋼超耐磨研磨桶的說明書有嗎? 不銹合金鋼超耐磨研磨桶的操作規程有嗎?

不銹合金鋼超耐磨研磨桶的操作規程有嗎? 不銹合金鋼超耐磨研磨桶的報價含票含運費嗎?

不銹合金鋼超耐磨研磨桶的報價含票含運費嗎? 不銹合金鋼超耐磨研磨桶有現貨嗎?

不銹合金鋼超耐磨研磨桶有現貨嗎? 不銹合金鋼超耐磨研磨桶包安裝嗎?

不銹合金鋼超耐磨研磨桶包安裝嗎? 手機版:

手機版: